Our products: vertical turbine pump, vertical wet pit pump, vertical oil sump pump, vertical condensation pump, right Angle gearbox

发布时间:2023/2/4 11:56:57

浏览次数:

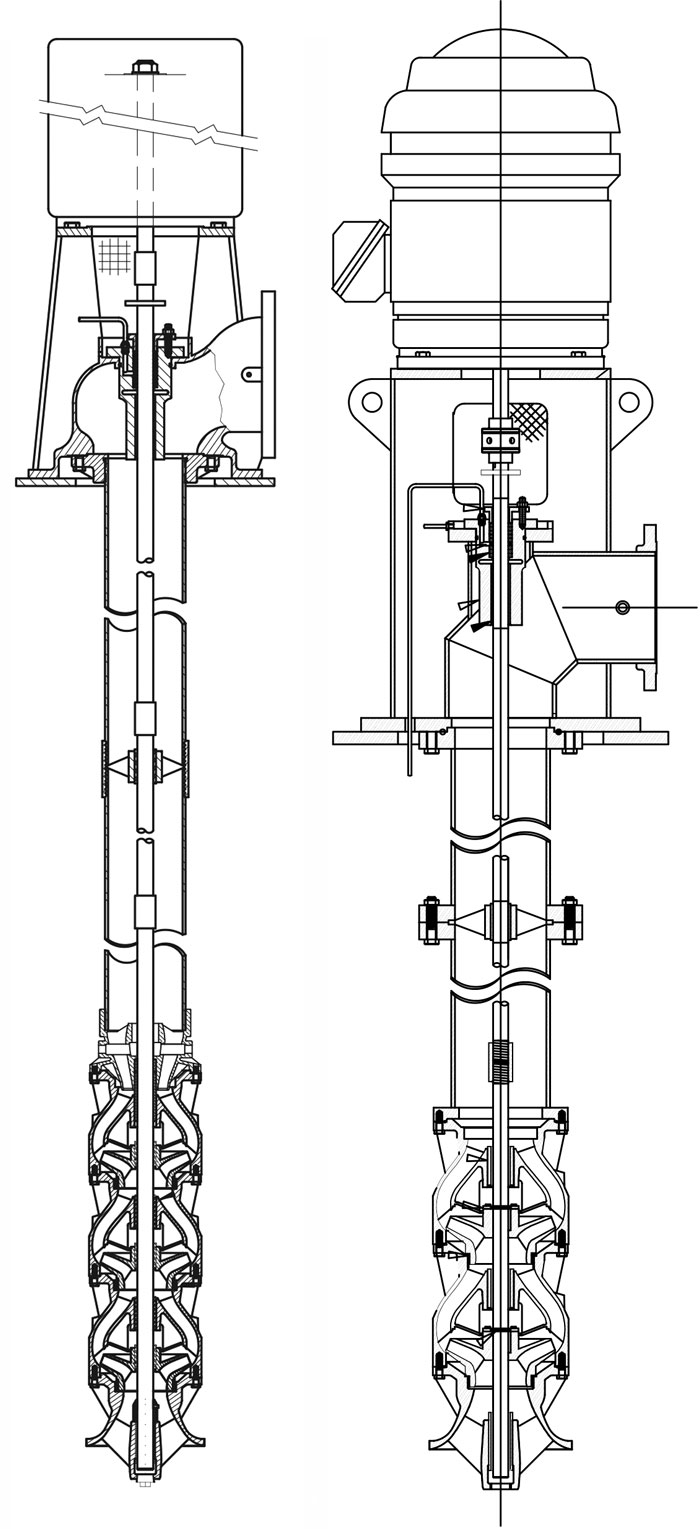

Image 1 (left). Deep well VTP. Image 2 (right). Short set VTP (Images courtesy of Hydraulic Institute)

Image 1 (left). Deep well VTP. Image 2 (right). Short set VTP (Images courtesy of Hydraulic Institute)A deep well turbine is usually installed in a drilled well with the first stage impeller laying below the water level of the pump. These pumps are self-priming, typically a multistage assembly, and are primarily used to transport water. The multistage assembly of a deep well turbine pump can be seen in Image 1. Transporting water from deep wells to the surface is the primary application of these pumps.

These pumps transport water to treatment plants, irrigation sprinklers and to faucets in homes. Short set pumps operate very similarly to deep well pumps. Short set pumps will often operate in water pits and typically have a maximum length of 40 feet as shown in Image 2.

Additionally VTPs can be installed in a suction barrel or can that is installed below ground level to provide additional suction head to the first stage impeller. These pumps operate typically as booster pumps or other applications where low net positive suction head (NPSH) is available.

Another unique application of a VTP is that the pump can be run in reverse and be used as a hydraulic turbine to generate power. When used in this application, the suction nozzle becomes the outlet of the turbine and the discharge nozzle becomes the inlet of the turbine. The efficiency of the pump as a turbine is comparable to the efficiency of the pump. Caution must be used, so please check with the manufacturer prior to using a pump as a turbine.

Copyright © 2002-2022 Hunan machinery manufacturing co., LTD. All Rights Reserved.

+8618507312158

WeChat Qr Code